The Business Challenge

Ice cream sticks or bars are delicious portions of frozen goodness on a handy little stick that makes devouring them easier! Invented back in the 1920s and loved around the globe, flavours can range from decadent creamy, gooey, nutty layers to the good old refreshing icy pole (which is really sugary water frozen on a stick ).

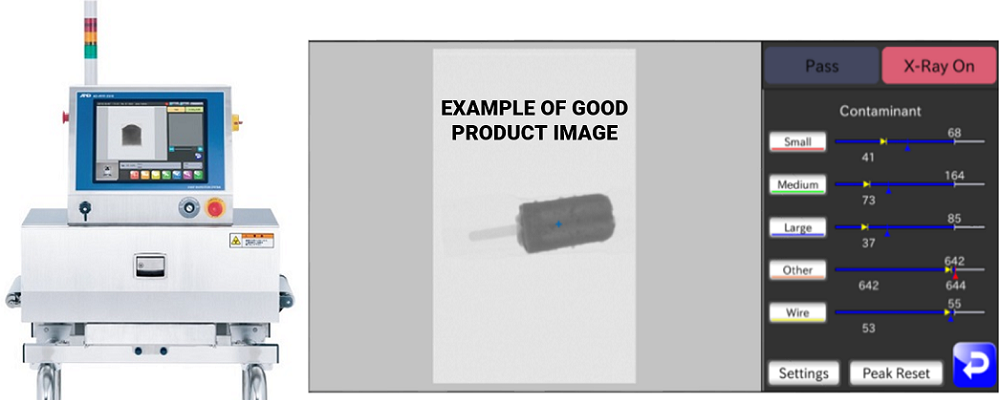

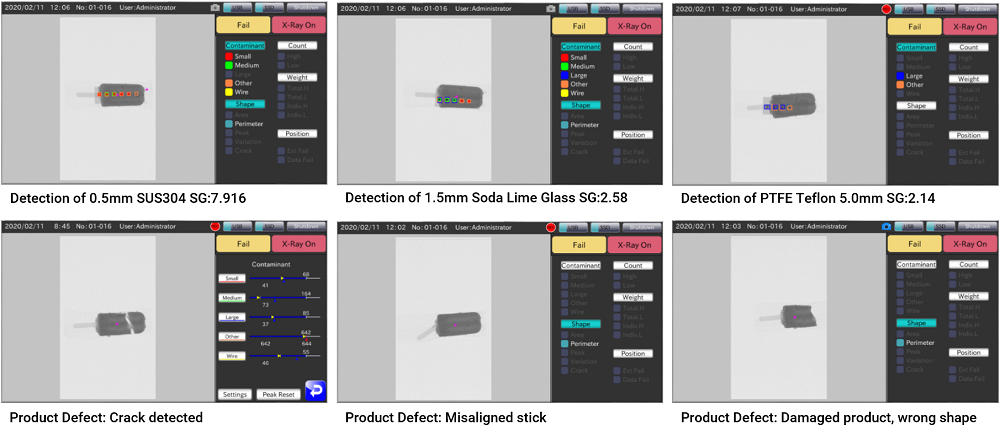

With the warm weather easing, we had a few leftover ice cream bars in the A&D fridge, so we thought we should run some tests on them to see what could be found or seen through our food inspection systems. Because some of the wrappers had metallised packaging, we decided to run it through the X-ray with a range of test cards. The food X-ray system software was configured to detect: contamination and product defects. We’ve taken photos of the results below.

…A little fun fact we found out when doing this test, Australia is one of the top three countries that consumes the most ice-cream!

Ha, go us!

The Results

Because A&D Inspection’s automated systems can process items so quickly and effectively, this reduces your risk and protects your brand from potential recalls.

Contact A&D Inspection today to find out how you can improve inspection on your production lines.

About A&D Inspection

Why Trust A&D Inspection?

From raw ingredients to the store shelves, product inspection is a key component of ensuring quality in your manufacturing facility, one you shouldn’t trust to just anyone.

- A&D is an established global company that has been a trusted provider of long-lasting and reliable measurement instrumentation for over 40 years.

- A&D provides checkweighers and metal detectors suitable for direct food contact, meeting USDA standards.

- Our systems can handle the environment and are designed to deliver reliable and repeatable results, and they are commonly used throughout the food and beverage industry today.

- Our intuitive software and user interface is easy to configure, making product changeover as simple as pressing a button.