The desorption kit consists of a quick-latching Camlock canister and water reservoir connected by some tubing. A sample of material from which gas is evolving is placed in a sample holder which, in turn, is placed in the body of the canister. The camlock lid is locked in place, and the accumulating gas increases pressure inside the water reservoir. Water is displaced and collects in a beaker for estimation of produced gas volume.

Gas may be produced at varying rates and gas expulsion trends could be a critical part of a project – a technician may be required to monitor and record the displaced water volume at high rates of expulsion, which can be a demanding and restrictive task. The ideal solution would be to include equipment that can accurately measure gas production and send data directly to a laptop or data logger. In this example here, A&D can provide that solution and significantly help to save time and effort.

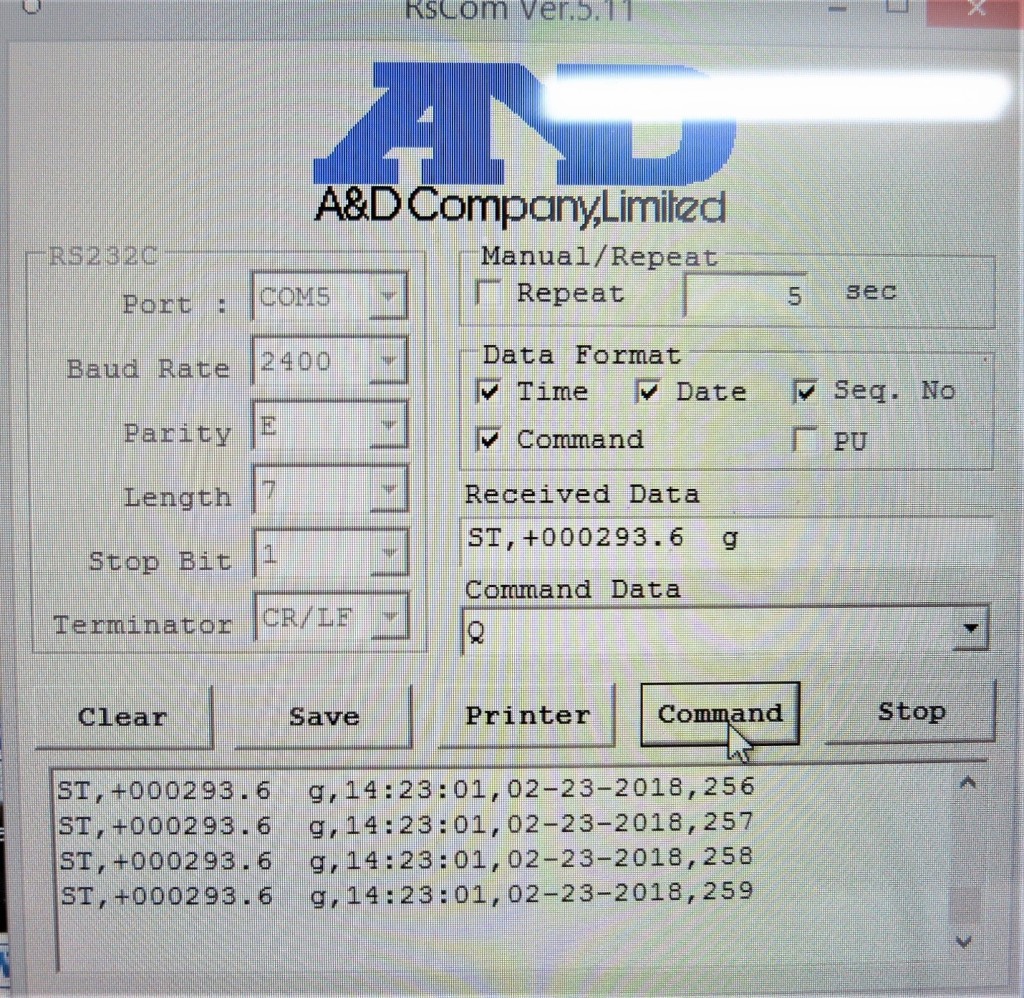

A beaker placed on the weigh pan allows the scale to measure the increasing weight of water, and stream data directly to your laptop via RS232 or USB cable. In this application, our software allows the user to set the preferred acquisition rate.

This type of solution can be applied in the resources industry with coal seam methane and unconventional gas exploration being prime candidates. Samples of fresh coal, drill cuttings or sidewall cores can desorb gas at measurable rates and the displaced water (mL) is a close approximation to the evolved gas volume (cc).

The kits are portable, straight-forward to use and disassemble for transport if necessary. The range of A&D scales complement the kits and allow the operator freedom to perform other duties rather than visually document the produced volumes. For a setup like this, you can use the EW-i Series Portable Triple Range balances, which can be approved for trade in accordance the National Measurement Institute of Australia.