The food inspection industry is rapidly evolving, and the X-ray food inspection market is no exception. E-commerce sector is having a significant impact on the X-ray food inspection market, as more and more products are being sold online. Businesses need to be able to ensure that their products are safe for consumption. Consumers are becoming more discerning, and they want to know that the food they eat is safe and high quality. This is driving demand for X-ray inspection systems, which can detect even the smallest defects in food products.

New regulations are being introduced all the time, and businesses need to be able to comply with them. The X-ray food inspection market is expanding rapidly as a result, as businesses seek to ensure that their products are compliant with all applicable regulations.

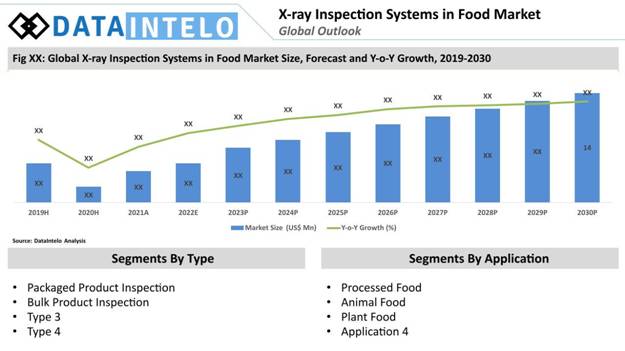

Aug 09, 2022 (Alliance News via COMTEX) — The global X-Ray food inspection equipment market size was US$ 1,461.2 million in 2021. The global X-Ray food inspection equipment market is forecast to grow to US$ 2341.4 million by 2030 by growing at a compound annual growth rate (CAGR) of 6.1% during the forecast period from 2022 to 2030.

Ref : marketwatch.com

On the Basis of Types:

The research report analyzes key factors such as production, revenue, price, size, advancement, future forecast, and market growth rate of each type, primarily split into:

- Packaged Product Inspection Equipment

- Bulk Product Inspection Equipment

On the Basis of Application:

The research report analysis the market segmentation, regional analysis, manufacture overview, and major applications/end users:

- Processed Food

- Animal Food

- Plant Food

Ref : digitaljournal.com

The Best Approach for selecting an appropriate X-ray inspection system

When it comes to quality assurance, manufacturers must go the extra mile to ensure that their products are up to standard. This means investing in systems like X-ray inspection systems, which can help identify and correct problems with products before they reach consumers.

To ensure product safety.

One of the primary reasons for investing in an X-ray inspection system is to maintain product safety. By identifying and correcting potential problems with products early on, manufacturers can help avoid any potential safety hazards later on.

Solution : ProteX X-ray AD-4991-3530

The ProteX X-ray AD-4991-3530 is a reliable system that can help manufacturers maintain product safety. This system is designed to detect even the smallest defects in food products, so businesses can be sure that their products are safe for consumption. With the ProteX X-ray AD-4991-3530, businesses can have confidence that their products meet all applicable safety regulations.

To improve product quality.

Another major benefit of using an X-ray inspection system is that it can help improve product quality. By detecting and correcting defects early on, manufacturers can produce higher quality products that meet or exceed customer expectations.

Solution : ProteX X-ray AD-4991-2510

The ProteX X-ray AD-4991-2510 is a system that can help manufacturers improve product quality. This system is designed to detect even the smallest defects in food products, so businesses can be sure that their products are of the highest quality. With the ProteX X-ray AD-4991-2510, businesses can have confidence that their products meet or exceed customer expectations.

To reduce manufacturing costs.

Finally, one of the biggest benefits of using an X-ray inspection system is that it can help reduce manufacturing costs. By identifying defects ahead of time, manufacturers can avoid having to spend time and money fixing them later on.

Solution : ProteX X-ray AD-4991-2515

An X-ray inspection system can help manufacturers reduce manufacturing costs by identifying defects early on. The ProteX X-ray AD-4991-2515 is a system that can help manufacturers reduce manufacturing costs. This system is designed to detect even the smallest defects in food products, so businesses can be sure that their products are of the highest quality. With the ProteX X-ray AD-4991-2515, businesses can have confidence that their products meet or exceed customer expectations.

Key steps for a manufacturer should follow when considering whether to purchase an x-ray system:

Conduct a Hazard Analysis

When considering investing in an x-ray inspection machine, manufacturers should conduct a Hazard Analysis for every product they produce, assessing the risk of contaminants being present. By doing so, they can identify where best to allocate their resources in order to maintain safe and contamination-free products. Additionally, this process can help identify potential hazards that may not have been considered otherwise, and allow for the development of preventive measures to mitigate these risks.

Identify Critical Control Points (CCPs)

An x-ray system is an important tool for detecting contaminants in food. When selecting a location to install an x-ray system, it is important to consider the critical control points in the production process. The x-ray system should be placed in a location where it can best detect contaminants in food. A CCP is a step or process essential to ensuring the highest levels of product safety; it’s the point at which control must be applied to reduce the risk of contamination to acceptable levels.

Define commercial and operational needs

It is important to first define your specific commercial and operational needs. Some questions you may want to ask yourself include:

- What specific foods do you need x-rayed?

- What are the maximum dimensions of the food items you need x-rayed?

- What are the minimum dimensions of the food items you need x-rayed?

- What is the maximum weight of the food items you need x-rayed?

- What is the minimum weight of the food items you need x-rayed?

- What is the thickness of the food items you need x-rayed?

- What is your budget for this project?

Assess the x-ray system’s key functions

The food x-ray system meets all of the key functionality requirements that were set for it. This system is able to quickly and accurately detect foreign objects in food, which helps to ensure the safety of the food supply. Additionally, the system is easy to use and provides clear images of the food products that are being scanned.

- Is it easy to use?

- Can operators be trained quickly to use the x-ray system?

- Does it enable quick product changeovers?

- Does it allow easy storage and retrieval of date-and-timestamped

- Images and data, for full traceability?

The food x-ray system’s key functions are to ensure that food is safe for consumption and to detect any foreign objects that may be present in the food. The system is also able to identify any abnormalities in the food, such as contamination or spoilage.

Consider final factors

Overall Equipment Effectiveness (OEE) is a measure of how effectively a machine is being used. OEE is calculated by dividing the amount of time the machine is running by the amount of time it should be running, and then multiplying that number by 100. This number tells you how much of the machine’s potential output is actually being achieved. The Food x-ray system must have an Overall Equipment Effectiveness (OEE) of 95% and a Total Cost of Ownership (TCO) of $2,000 per year. This system is a great value for the money and is highly effective in detecting food contaminants.

How accurate is A&D’s ProteX X-ray system to detect foreign objects?

A&D’s ProteX X-ray system is a great choice for a complete X-ray inspection. It uses advanced technology to detect a wide variety of contaminants and hazards, so you can be sure your product is safe for your customers. With its fast and accurate detection capabilities, the ProteX system is an ideal choice for complete X-ray inspection. This machine is able to quickly and accurately detect foreign objects in food, which helps to reduce the risk of contamination.

Additionally, the system is easy to use and provides clear images of the food products that are being scanned.

When looking for a complete x-ray inspection system, the A&D ProteX X-ray system is an excellent option. It has five features that make it a great choice for businesses of all sizes.

Accurate detection of the smallest contaminants.

Precise detection of the smallest of foreign contaminants is key when choosing a complete x-ray inspection system. By ensuring that all areas of your product are inspected, you can minimize the risk of any undetected defects reaching your customers.

Types of contaminants X-ray can detect.

- Metal

- Non-ferrous metals in foil, including stainless steel

- Glass

- Bone (calcified)

- PVC plastic

- TFE (Teflon) plastic

- Ceramic or concrete

- Flavor/sugar clumps

Estimation of the mass of the product

When choosing a complete ProteX X-ray inspection, it is important to estimate the weight of the product in order to determine if it meets desired weight parameters. If the weight falls within the desired range, then the product can be approved and sent on its way.

It can quickly and easily measure the weight of an item without needing to take it out of the packaging. This makes it a fast and efficient way to get an accurate reading of a product’s weight.

Shape detection features

By using ProteX X-ray to inspect products, businesses can ensure that their products are consistent and meet all the required specifications. This can help businesses avoid product

recalls and save money in the long run. It is helpful in finding inconsistencies like incomplete, cracks or broken products.

Screening Function Feature

ProteX X-ray can help to confirm product integrity and reduce the number of false rejections. By using an x-ray inspection system, you can quickly and easily identify any potential defects in your products. This can help to improve quality and ensure that your products meet all safety requirements. It is important to consider the needs of your business and the products you are trying to protect. A system that is too basic may not provide the level of security you need, while a system that is too sophisticated may be more than you need and could lead to more false rejections.

Best Food X-Ray Inspection Series in Australia

With over 50 years of experience in x-ray inspection, A&D has the knowledge and expertise to help you find the perfect system for your needs. We offer a wide range of systems, from entry-level models to high-performance systems, so you can find the perfect fit for your application. Our team of experts are always available to answer any questions you may have about choosing and using an x-ray inspection system such as ProteX X-ray AD-4991-3530, ProteX X-ray AD-4991-2515 & ProteX X-ray AD-4991-2510.We take a consultative approach, working with you to identify your specific needs and recommend the best system for you.