A&D Inspection recently assisted a protein powder manufacturer to fine tune their existing quality control process and help with increasing the reliability, safety and efficiency of their production lines.

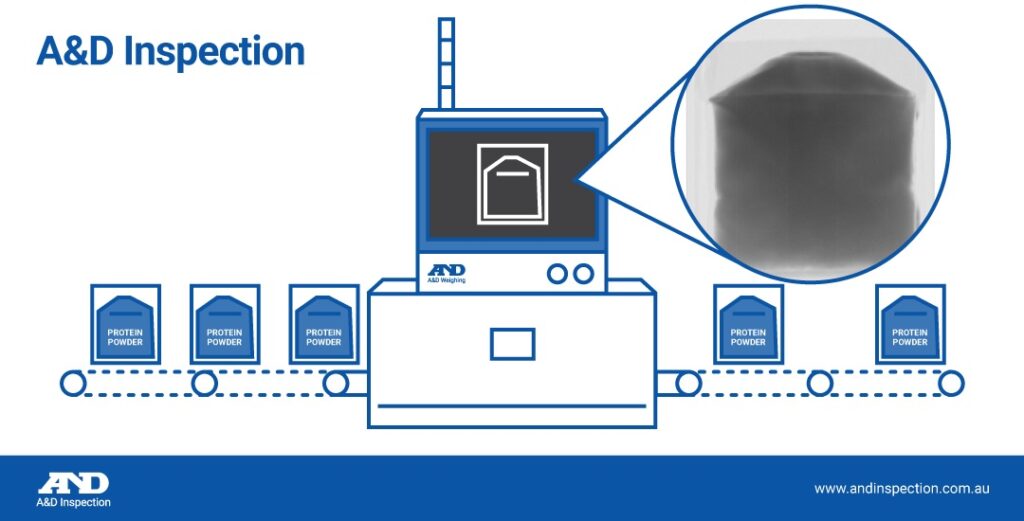

The innovative A&D ProteX X-ray System, allows the customer to detect and identify packaged product that contains foreign contaminants and remove these reliably from their packaging line to avoid costly product recalls.

The Business Challenge:

A protein powder manufacturer, already recognised for setting high quality standards, has committed themselves to the fight against food wastage. They have recently been looking into alternative technologies to reduce the quantity of product that they are forced to dispose of in situations where a batch of final product is suspected of containing contaminants and quarantined.

The customer currently uses a metal detector during their raw materials manufacturing process, but in the event of a potential tampering situation, entire large batches from a recall would be identified and disposed of, inflicting significant expense on the customer due to the un-saleability of their potentially perfect product, as well as the damage to their respected brand.

The Results

After some preliminary tests of their product samples running through our ProteX X-ray System in Adelaide, the customer could clearly see the benefits of having a fail-safe system at the end of their finished goods line, and have since purchased a ProteX AD4991-2515 X-ray Inspection System to ensure only 100% inspected final product leaves their warehouse.

Protein X Ray Inspection:

A&D are able to meet the stringent inspection and sensitivity specifications and guarantee an easy installation and excellent value from a total cost of ownership perspective. With the ProteX “Auto Setup” function, new products can easily be setup in minimal time.

X-ray technology that meets or exceeds the quality requirements of food manufacturers and retail standards.

High precision inline detection of many contaminants including and not limited to: glass, metal, stone, bones, some plastics, etc

Automated functions reducing times for calibration or servicing

Reliable inspection of more than 33.000 packs a day

Total peace of mind for the manufacturer and consumers

So, what are the benefits of X-ray inspection machines?

Reducing food waste

The main benefit of implementing an X-ray inspection system into a production line is the ability to perform in-line quality checks whilst the products are still at the manufacturer’s site. This ensures better inspection and minimises product waste.

Protein powder in particular, is often packaged in foil packaging to guarantee product quality and product life, and is unable to be inspected using a metal detector. A food-grade X-ray system however, can identify potential foreign contaminants (such as metal, rubber, glass, stone and dense plastics).

Quality assurance:

Whilst detecting the presence of physical contaminants is a key role of modern food X-ray systems, these systems can also carry out several other quality assurance tasks to ensure product quality. X-ray systems can perform a variety of inline product integrity checks, such as ensuring that fill levels are accurate, inspecting packaging for damage, measuring mass, locating broken or missing products and ensuring that all necessary components are present.

Speeding up turnaround times:

With a fail-safe system at the end of a finished goods line, new products can be inspected and packaged quickly. These automated functions also reduce the amount of time spent on servicing or calibration, so products can be manufactured and shipped faster and more economically.

An inline X-ray system can also increase Overall Equipment Effectiveness (OEE) and offer a higher ROI. One X-ray machine is capable of completing numerous inspection tasks at once, and a single set-up screen can make line changeovers easier and faster while reducing production line downtime and operator errors.

Protecting brand reputation:

Contract packagers and food manufacturers alike are increasingly eager to inform their customers that they have incorporated X-ray inspection into their QA process, as it adds a higher level of brand recognition and customer approval. This not only increases customer retention and satisfaction, but it can also increase the market share of these businesses by giving their customers a boost of confidence in their brand.

Regulatory compliance and risk management

Compulsory X-ray inspection may not be a legal requirement yet, but if any legal proceedings were to occur as a result of food contamination, manufacturers will be able to demonstrate that they have implemented the correct procedures to prevent and manage any identified risks in the production process.

If you would like to learn more about A&D Inspection’s food X-ray systems, or you have any questions about any of the other products in our range, don’t hesitate to fill in our online contact form here we’re here to help answer your questions.

Related Case Study: X-ray | Inspecting Protein Powder