Being able to provide consistent quality products is important for the success of every business, especially in the food and beverage sector. Consistency not only ensures customer satisfaction, but also improves your brand reputation, and builds trust and loyalty.

A&D Inspection offers checkweighing, metal detection and X-ray inspection solutions that allow production and manufacturing facilities to maintain high quality consistently across all product lines.

Our inspection equipment will improve production quality, reduce product giveaway, and ensure products are free of foreign contaminants from day one.

ROI in Product Inspection Processes of Packaging

A&D Industrial Metal Detectors are manufactured to detect metal contaminants in packaged products to ensure the delivery of safe consumer products.

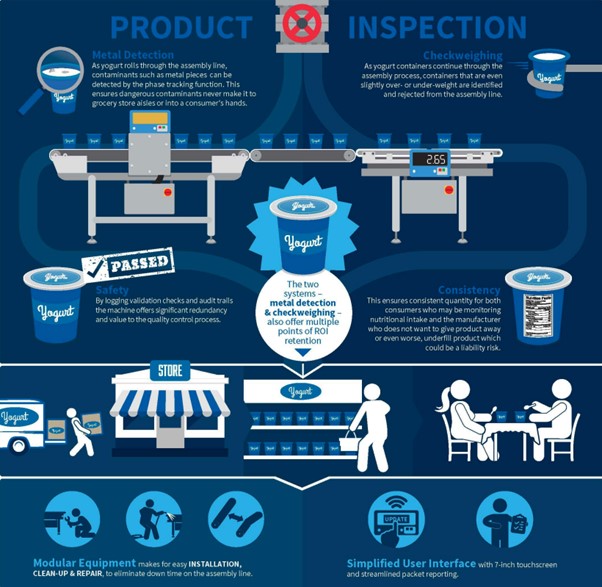

As products roll through the assembly line, contaminants such as metal pieces can be detected by the phase tracking function. This prevents dangerous contaminants from making it to store shelves or into a consumer’s hands, protecting the welfare of your customers as well as safeguarding your brand reputation.

Once the products have been cleared of foreign contaminants, they continue through the assembly process to the checkweighers. Our EZI-Check inspection systems include intelligent checkweighers that are specially designed to weigh, classify and segregate products based on weight.

Packaged products that are even slightly over- or under-weight will be identified and rejected from the assembly line, to ensure that you supply the correct weights to retail stores and customers every time.

A reliable checkweighing system ensures consistent quantity in every package. This is important not only for customer confidence, but also to reduce your product giveaway and prevent underpacking, which could be a liability risk.

When combined, these inspection systems – X-ray, metal detection and checkweighing – can offer multiple points of ROI retention:

- Checkweighers are a cost-effective solution in the long term, as they reduce manual labour and error. Instead of having to manually weigh and sample each individual package, the process can now be sped up with the automatic system.

- When products are inconsistent in quality, businesses may be forced to recall them. Product recalls are extremely costly, plus there may also be legal fees, financial settlements and potential fines. Your brand and reputation may also be tarnished, and you may take years to recover from the damage. It is better to prevent this by having a good inspection system in place from the start.

- A&D’s modular equipment makes it easy to install, clean up and repair, eliminating down time on the assembly line.

- A&D inspection solutions come with a simplified user interface with easy-to-operate 7-inch colour touch panel and streamlined packet reporting.

A&D Inspection can help your business increase quality control with our range of innovative, accurate and reliable solutions that are suitable for your application. To find out more about our checkweighing systems, X-ray or metal detection solutions, get in touch with our team today.